This Page is about Alternative Building techniques. Most people build and/or live in stick built homes, those box shaped un-economic, un efficient, energy wasting, homes.

We have used the most inefficient building methods for hundreds of years. Wooden stick houses waste tremendous amounts of energy, steel and glass buildings fall into the same category. Although techniques are getting better there are better, cheaper, more efficient ways to build things and keep them a comfortable climate inside.

However for thousands of years scocieties have build and lived in other forms of housing. Some people lived in cave dwellings, some in adobe houses, some in homes in the side of cliffs. Others in castles or palaces made with large stones. All of these have MASS. Heat or cool are absorbed by the thick material that made up the walls and slowly released it, thus keeping the structure a more constant temperature.

Still others lived in smaller dwellings such as tipi's or igloos. Though it might seem they would be extremely hot or cold, depending on type and time of year, they were not. A small fire inside to keep them warm with a hole on the top to let the smoke out, or an open flap to let the breeze in.

Still there are others, however, modern materials and ways of building expand the type of home you can build and the way you can build it. There are also Many ways you can POWER hour house. See Alternitive Energy page.

Here I will breifly explain about Other types of building, and also have links to other sites and books or videos dealing with the same building type that explain the method furthur. Also you can combine types to have your own unique home.

|

Domes are what it says, Domes.

There are two type of dome homes, the pictured Geodesic Domes designed by Buckminster_Fuller , made from wood, and then there are Monolithic Domes. usually made from Cement. These provide a stronger structure and more MASS. There is a new type of dome home being developed by Sustainable Living Systems called "The Core Home" Basically, it is a hollow Tubular dome structure surrounded by wood panels just as in a regular geodesic dome. But the best part of this idea is that there is a coolant fluid running through the Tubular pipe structure with a pump in the top of the dome that keeps the fluid in constant motion. This fluid is then sent to a ground heat sink that stabilizes the temperature. Thus the whole house remains relatively a constant temperature. This fluid transfers the heat or the cool throughout the house. Heats up at the top of the house, and cooled at the bottom. or if it is cold out, collects the heat of the ground, and transfers it through out the structure. This amazing idea gives the net energy usage as ZERO. since you are using a subterranean heat sink to keep the house at a relatively constant temperature. The average temperature of the earth below the frost line is appropriately 65 degrees. To augment the savings you could use a solar pump to push the fluid through the pipes, and add Solar Panels to create more energy for your home usage. For a better explanation visit the website Sustainable Living Systems. |

|

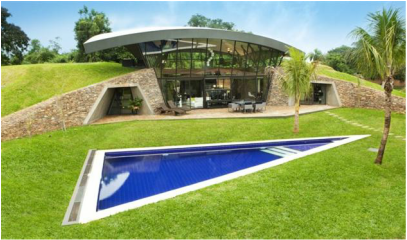

Underground or "Earth-sheltered" homes are nestled into the earth, either totally or in part. It doesn't have to be a Hobbit House, like the one Frodo and Bilbo Baggins lived in, in the Hobbit books. But they can be similar.

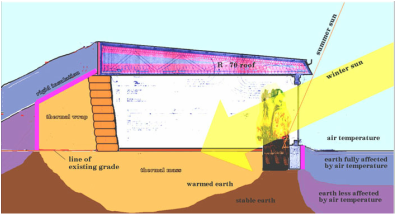

The advantages of underground construction are considerable. About six feet under the earth, you will find that the temperature varies by only a few degrees year round. While this temperature might be too cool for general living comfort, you can use the stability of the earth's temperature to moderate the thermal fluctuations of the house. This means that it will take much less energy to either heat or cool the house. If you dig into a south-facing hillside to build, or berm the north part of the house with soil, you can take advantage of this. The part of the house that is underground needs to be well insulated. The south facing side should have a maximum amount of windows to let in the sunlight. This will enable the house to stay warm in the winter. Being that the top of the house is under the earth, this allows a good place for a garden to grow your own food. This leads us to our next style of underground home, the Earth Ship. |

|

The Earthship is another type of underground home. The basic earthship design incorporates substantially bermed, passive solar architecture. The primary retaining walls are constructed with used tires, which you can usually get for free at local tire stores. then are filled with earth and stacked up like bricks.

The interior surface of the tires is then plastered with adobe or cement so the tires don't normally show. Others have used empty aluminum cans or colored bottles mortared into lightweight, curvable walls. Earthships often employ many ecological concepts, such as water catchment from the roof, reuse of greywater, composting toilets, indoor gardening, etc. AS with Underground, or earth burmed homes, people usually choose a south facing direction for the windows, using solar radiation to heat the house. Another of this type of home is the use of a front hallway near the windows, and a large mass wall behind that warms up from the heat from the sun and slowly releases that heat at night to warm the house. Next to the windows is usually a garden where they can grow food all year round. |

Shipping containers can be readily modified with a range of creature comforts and can be connected and stacked to create modular, efficient spaces for a fraction of the cost, labor, and resources of more conventional materials. With the green theme growing in popularity across every stretch of the world, more and more people are turning to cargo container homesfor green alternatives for office, and even new home, construction. There are countless numbers of empty, unused shipping containers around the world just sitting on the shipping docks and taking up space. The reason for this is that it’s too expensive for a country to ship empty containers back to the their origin in most cases, it’s just cheaper to buy new containers from Asia. The result is an extremely high surplus of empty shipping containers that are just waiting to become someone’s home or office.

|

Strawbale House Construction

A Brief Overview by Thomas J. Elpel, Author of Living Homes Strawbale buildings are all the rage in alternative construction today, and with good reason--they are cheap, easy to build, and very energy efficient. Strawbale buildings look similar to adobe, with massive walls, wide window sills and typically rounded corners, but with the added benefit of a higher insulation value. The soft, sometimes curvy edges of strawbale construction can lend a fairy tale look to the finished structures. The fun part of strawbale construction is that anyone can do it. Anyone can help stack the fluffy, oversized bricks in place. Strawbale homes and outbuildings were first developed by pioneers in the Sand Hills of Nebraska where there was lots of straw, but few trees. The early pioneers built houses of sod, up until the late 1800's when baling technology provided the first compressed, string-tied rectangular bales. The next logical step was to stack those bales like bricks to make warm walls. Strawbale buildings from the early 1900's are still in use and in excellent condition today. |

|

Due to publicity in the 1980's and 1990's there are now strawbale buildings popping up all over the world--in wet and dry climates, from hot southern environments to chilling northern extremes.

Strawbale homes are very well insulated. The orientation of the straw in the bales makes some difference in the insulation value. Bales laid flat (with strings running around the top and bottom) rate about R-2.4 per inch while those laid on edge (with strings running around the sides) rate R-3 per inch. However, the bales are usually wider when laid flat than on edge, giving a higher overall R-value. The bales are slightly stronger too, when laid flat. There are two types of strawbale houses. One type has load-bearing walls, where the weight of the roof is supported by the bales, while the others are non-load bearing, where the roof is supported by a framework and the bales are filled in afterwards. There are advantages and disadvantages to either approach... |

Typical support structures for non-load bearing strawbale buildings include conventional lumber framing as well as timber framing, framing with poles or logs, or concrete posts and beams. The support structure holds up the roof, taking the pressure off the bales (and the builder). Besides, a supporting framework enables you to put up the roof first, so that the rest of the work can proceed inside the shelter, protecting yourself, your tools and the strawbales from the weather. That's important since it only takes one rainstorm to soak the tops of the unprotected bales, quickly rotting out your good work.

On the other hand, a supporting framework often requires more lumber than you would use with load-bearing walls, and the framing tends to get in the way of the bales, requiring extra design work to position the framing for minimal interference with the walls, and/or to notch into the bales to fit around the framing. The strawbale home pictured here is a non-load bearing structure built by another neighbor. It is also featured in Living Homes.

article from http://www.hollowtop.com/

http://www.homedesignfind.com/green/straw-building-blocks-make-warm-sustainable-homes

On the other hand, a supporting framework often requires more lumber than you would use with load-bearing walls, and the framing tends to get in the way of the bales, requiring extra design work to position the framing for minimal interference with the walls, and/or to notch into the bales to fit around the framing. The strawbale home pictured here is a non-load bearing structure built by another neighbor. It is also featured in Living Homes.

article from http://www.hollowtop.com/

http://www.homedesignfind.com/green/straw-building-blocks-make-warm-sustainable-homes

Adobe

Adobe is an amazingly versatile material. For hundreds of years, it dominated construction in the American Southwest and it can be used economically in a full range of structures. In recent years, modern building techniques have further increased adobe's flexibility.

Adobe bricks are most often made into units weighing less than 100 pounds and small enough that they can quickly air dry individually without cracking and subsequently assembled, with the application of adobe mud, to bond the individual bricks into a structure. Modern methods of construction allow the pouring of whole adobe walls that are reinforced with steel.In dry climates, adobe structures are extremely durable, and account for some of the oldest existing buildings in the world. Adobe buildings offer significant advantages due to their greater thermal mass, but they are known to be particularly susceptible to earthquake damage if they are not somehow reinforced.

Adobe bricks are most often made into units weighing less than 100 pounds and small enough that they can quickly air dry individually without cracking and subsequently assembled, with the application of adobe mud, to bond the individual bricks into a structure. Modern methods of construction allow the pouring of whole adobe walls that are reinforced with steel.In dry climates, adobe structures are extremely durable, and account for some of the oldest existing buildings in the world. Adobe buildings offer significant advantages due to their greater thermal mass, but they are known to be particularly susceptible to earthquake damage if they are not somehow reinforced.

Earthbag homes

|

Building with earthbags (sometimes called sandbags) is both old and new. Sandbags have long been used, particularly by the military for creating strong, protective barriers, or for flood control. The same reasons that make them useful for these applications carry over to creating housing: The walls are massive and substantial, they resist all kinds of severe weather (or even bullets and bombs), and they can be erected simply and quickly with readily available components. Burlap bags were traditionally used for this purpose, and they work fine until they eventually rot. Newer polypropylene bags have superior strength and durability, as long as they are kept away from too much sunlight. For permanent housing the bags should be covered with some kind of plaster for protection.The use of sandbags in house building reduces CO2 emissions by up to 95-percent compared to standard brick built walls and there is no processing of materials prior to use in the construction.In addition, sandbags can be up to 40-percent cheaper than brick. Couple this with the fact that when sandbag houses are completed with plastered exterior and interior walls, they will look identical to a house built from conventional materials.

|

Insulated Concrete Forms (ICF)

|

WHAT ARE ICF’S (Insulating Concrete Forms)Insulating concrete forms (ICFs) are hollow foam blocks which are stacked into the shape of the exterior walls of a building, reinforced with steel rebar, and then filled with concrete. ICFs combine one of the finest insulating materials, Expanded Polystyrene (Styrofoam), with one of the strongest structural building materials, steel reinforced concrete. The result is a wall system of unmatched comfort, energy efficiency, strength and noise reduction. The forms, made of foam insulation, are either pre-formed interlocking blocks or separate panels connected with plastic ties. The left-in-place forms not only provide a continuous insulation and sound barrier, but also a backing for drywall on the inside, and stucco, lap siding, or brick on the outside. Although all ICFs are identical in principle, the various brands differ widely in the details of their shapes, cavities and component parts. .Whatever the differences among ICF brands, all major ICF systems are engineer-designed, code-accepted, and field-proven.

|

|

BENEFITS TO HOME OWNERS

Comfort - Houses built with ICF walls have a much more even temperature throughout the day and night. They have virtually no “cold spots”, and sharply fewer drafts. Solidity - The rigidity of concrete construction reduces the flex in floors and cuts shifting and vibration from the force of the wind or the slamming of a door. Concrete houses survive high-force winds like hurricanes far better than wood homes. And when properly reinforced, they should also withstand earthquakes well. Quietness - About one-sixth as much sound gets through an ICF wall compared with an ordinary wood frame wall. This sharply cuts the intrusion of noise from outside. Energy efficiency - The superior insulation, air tightness, and mass of the walls cut the amount of energy needed for heating and cooling by 30-40%. This can save $200-300 per year in a typical home. In addition, it allows the installation of smaller heating and cooling equipment. That can reduce the initial cost of a house by over a thousand dollars. Design flexibility - ICF houses can be completed with almost any interior and exterior finishes and can take any shape as easily as wood frame. In fact, some interesting effects, such as curved walls and frequent corners, can be less expensive to build into an ICF home. |

|

Internationally Proven & Code-Accepted

Originally developed in Europe (where concrete home building is standard) ICF Systems have been used successfully around the world for more than 30 years. Thousands of ICF homes have been built in recent years throughout the United States and Canada. They have proven successful in every region and climate, from Orlando to Calgary. ICF systems are accepted by all the major model codes in the U.S., and by the R-2000 program in Canada. *Fast to Learn & Easy to Use Although it looks new and different, anyone with construction experience can quickly get up to speed with ICF’s. An ideal crew has a mix of concrete placement and carpentry experience. Once the crew has some practice, each ICF built home requires less skilled labor and less total labor than a wood-framed home. ICF’s are very lightweight, so crews stay fresh through the day. Likewise, ICF’s present no problem for the sub-contractors who come after the walls are poured. Since holes, chases, and rectangles are easily cut into ICF’s with a knife or saw, installation of mechanical systems is a snap. The fastening of drywall and lap siding is just as fast and easy. And mid-course corrections, such as moving an opening, are no big deal - just saw it out and reform. It’s not more difficult to make changes to an ICF wall - it’s just different. INFO FROM http://www.icfdirect.com/ |

Structural Insulated Panels (SIPs)

|

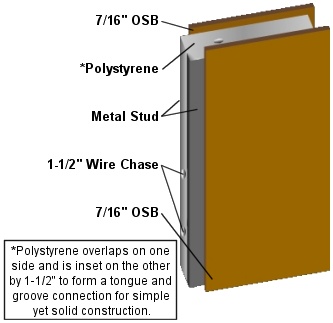

Panels made from a thick layer of foam (polystyrene or polyurethane) sandwiched between two layers of Oriented Strand Board (OSB), plywood or fiber-cement. These are used for walls, roofs, and floors. They resist loads caused by wind, snow, and seismic activity. SIPs have 1-1/2" pre-cut wire chases in necessary locations. The horizontal wire chases line up with the wire chases in the neighboring panel. Each panel is designed to assemble together using the tongue and groove as the connection point. Either grabber screws or 8 penny ringshank nails can be used to secure the panels by going through the OSB into the Metal spline making the connection even more solid |

Hempcrete Homes

In Europe, hemp has been used for years in construction, with recent projects including a seven-story office tower in France, a department store in the United Kingdom and the home of England’s Prince Charles.

Once solidified, the result is a material that weighs about an eighth of traditional concrete, is virtually fireproof, and unlike concrete, allows moisture to pass through, reducing problems with mold and mildew. The material also does not rely on petrochemicals.

You can install hempcrete in a few ways. One, as a slurry, put in between forms and packed into place, as hempcrete blocks similar to bricks, and pumped or blown in, similar to how concrete is pumped in.

As time goes on, hempcrete gets harder and harder, eventually becoming as hard as rock. check out the video below to learn more about this great building product.

you can also check out my other website about Hemp and other hemp products HERE

Once solidified, the result is a material that weighs about an eighth of traditional concrete, is virtually fireproof, and unlike concrete, allows moisture to pass through, reducing problems with mold and mildew. The material also does not rely on petrochemicals.

You can install hempcrete in a few ways. One, as a slurry, put in between forms and packed into place, as hempcrete blocks similar to bricks, and pumped or blown in, similar to how concrete is pumped in.

As time goes on, hempcrete gets harder and harder, eventually becoming as hard as rock. check out the video below to learn more about this great building product.

you can also check out my other website about Hemp and other hemp products HERE

Air-crete

|

“What is Air-crete? Air-crete is a lightweight cementitious material that contains stable air cells uniformly distributed throughout the mixture. It is a concrete which utilizes a stable air cell rather than traditional aggregate. It is also called cellular concrete, foam concrete, light weight concrete, aerated concrete etc. Typical concrete has a density of 140 lb/cu.ft. Air-crete densities range down to 20 lb./cu. ft. |

|

|

What is the correct water to cement ratio for the cement water slurry?

Typically, a (1 to 2) water to cement ratio slurry is used as a base mixture for Air-crete. The water cement ratio may be varied according to specific project requirements. Does Air-crete contain either fine or course aggregate? Air-crete may contain sand but not coarse aggregates. Air-crete is designed to create a product with a low density and a relatively lower compressive strength when compared to plain concrete. The typical density range of Air-crete is 20 – 60 lbs/cu.ft. which develops a corresponding compressive strength range of 50 psi – 930 psi. When higher compressive strengths are required, the addition of fine and less foam will result in a stronger concrete with resultant higher densities. |

What type of cement is appropriate for Air-crete?

Air-crete may be produced with any type of portland cement or portland cement & fly ash mixture. The performance characteristics of type II, type III and specialty cements carry forward into the performance of the Air-crete.

What are the advantages of Air-crete?

There are many benefits to Air-crete in the appropriate application. It is inexpensive to produce, it has good compressive strength, it bonds well, easy to work with, self compacting, self leveling, uses less material, and offers enhanced sound and heat insulating properties. Air-crete is very easy to clean up and can be removed with only hand tools.”

from http://www.naturalbuildingblog.com/air-crete-building/

Air-crete may be produced with any type of portland cement or portland cement & fly ash mixture. The performance characteristics of type II, type III and specialty cements carry forward into the performance of the Air-crete.

What are the advantages of Air-crete?

There are many benefits to Air-crete in the appropriate application. It is inexpensive to produce, it has good compressive strength, it bonds well, easy to work with, self compacting, self leveling, uses less material, and offers enhanced sound and heat insulating properties. Air-crete is very easy to clean up and can be removed with only hand tools.”

from http://www.naturalbuildingblog.com/air-crete-building/

Newer Building Styles

Here are some newer building styles that I have seen on videos on Youtube, there are more videos, but they are basically the same.

https://www.youtube.com/watch?v=BvzGfth-mXo

https://www.youtube.com/watch?v=BvzGfth-mXo

Gablok Insulated Blocks

The Gablok concept includes a series of insulated wooden blocks, insulated beams, lintels, and a customized floor system to efficiently construct the exterior and interior walls of the wooden house, all by yourself. The system has been validated by design offices in terms of acoustics, stability, and energy performance.

3D Printed homes.

|

YES, 3D printed homes. Quicker, more efficient, less waste. Any size from studio to 3 bedroom, with all the conveniences.

|

|

WoodCrete Homes

Similar idea to Hempcrete. These use wood chips and cement instead of Hemp and Lime binder.

Exterior and interior load-bearing walls from H-form Isotex® cement-bonded wood fibre blocks of density 510 ± 10% kg/m³ to be laid dry and staggered by half a block, cast with concrete every 5-6 layers and with a single continuous cavity for concrete casting

The wall is reinforced with horizontal and vertical steel rods at 25 cm intervals and concrete of a consistency of no less than S4.

The range of blocks is complete with a number of special units such as half-blocks, corner blocks, flooring curb blocks, architrave blocks and pillar blocks.

Structural blocks must have CE markings in accordance with the European Technical Assessment (ETA) and harmonized European standard EN 15498, certification of thermal transmittance (U-value) according to European standards UNI EN ISO 6946, UNI 10355 and EN 10211, thermal and humidity characteristics provided for by Presidential Decree 59/09, acoustic testing according to UNI EN ISO 140 and UNI EN ISO 717, fire resistance testing with loaded walls according to EN 1365-1 and EN 13501-2 and certification of materials in compliance with requirements for green construction building released by competent authorities.

Lego Homes

Build a house out of Giant LEGOS. YES I said LEGOS!!

Well, Not EXACTLY legos, but inspired by and pretty much the same as LEGOS. I have always thought that building a house out of Giant legos would be the perfect way to build. How quickly could you build a house out of giant legos. Well now they have a system to do just that.

Imagine a building material that is:

High Compressive Strength

High Tensile Strength

Water Resistant

Very High R-Value

UV Resistant

Light Weight

Earth Friendly “GREEN”

Field Modifiable

Bacteria Resistant

Mold Resistant

Good Sound Absorption Qualities

Imagine a building material that locks tight with no special tools, no glue, no nails, no cement; they just snap together. Lok-N-Blok is designed to incorporate any windows, doors, and roof systems. Electrical, plumbing, and utilities are easily installed in Lok-N-Blok structures. Exterior and interior wall materials such as traditional siding and drywall are easily installed over Lok-N-Blok walls.

Imagine building stronger, building faster, building in any climate. Imagine a system that is also:

GREENThe base material, Enveon20, is made from carbon and hydrogen and is manufactured without any dangerous emissions.

Scrap produced from both the manufacturing process and the jobsite can be recycled.

Lok-N-Blok is durable and safe, reduces labor and material costs, and gets buildings up in record time while remaining respectful of the environment.

Well, Not EXACTLY legos, but inspired by and pretty much the same as LEGOS. I have always thought that building a house out of Giant legos would be the perfect way to build. How quickly could you build a house out of giant legos. Well now they have a system to do just that.

Imagine a building material that is:

High Compressive Strength

High Tensile Strength

Water Resistant

Very High R-Value

UV Resistant

Light Weight

Earth Friendly “GREEN”

Field Modifiable

Bacteria Resistant

Mold Resistant

Good Sound Absorption Qualities

Imagine a building material that locks tight with no special tools, no glue, no nails, no cement; they just snap together. Lok-N-Blok is designed to incorporate any windows, doors, and roof systems. Electrical, plumbing, and utilities are easily installed in Lok-N-Blok structures. Exterior and interior wall materials such as traditional siding and drywall are easily installed over Lok-N-Blok walls.

Imagine building stronger, building faster, building in any climate. Imagine a system that is also:

GREENThe base material, Enveon20, is made from carbon and hydrogen and is manufactured without any dangerous emissions.

Scrap produced from both the manufacturing process and the jobsite can be recycled.

Lok-N-Blok is durable and safe, reduces labor and material costs, and gets buildings up in record time while remaining respectful of the environment.

OTHER LINKS

Factors concering energy efficiency

Alternitive building books and videos from Cal*Earth

greenhomebuilding.com

dirtcheapbuilder books

http://www.northcoast.com/

dreamgreenhomes.com Source for alternitive building plans

Dave's Dome Info Page

More Dome Picts

Monolithic Domes

Pictures of a dome in construction

Dome construction Co

Sustainable Living Systems.

http://www.monolithic.org/

Underground

http://www.daviddarling.info/encyclopedia/E/AE_earth-sheltered_buildings.html

http://www.earthshelteredhome.com

The Fifty Dollar and Up Underground House Book

Earthship

greenhomebuilding.The Complete Book of Underground Houses

http://www.homedit.com/earthship-homes-made-of-recycled-tyres

http://www.daviddarling.info/encyclopedia/E/AE_earthship.html

Shipping container

http://weburbanist.com/2008/05/26/cargo-container-homes-and-offices

Adobe

http://en.wikipedia.org/wiki/Adobe

http://www.adobebuilder.com/

http://oikos.com/library/adobe/

Earth Bag

http://www.earthhomesnow.com/sandbag-houses.htm

ICF

The Benifits of ICF

More Pictires of ICF building in progress NKS

ICF DIRECT

Build Block

Quad Lock

California Energy Commission

SIP

More info on SIP

betterbuilding.com

www.ibpanels.com

HEMPCRETE

http://www.hemp.org/news/hempcrete-hemp-building-materials

Aircrete

http://www.domegaia.com/air-crete.html

© !deaman !nk. 2021

Factors concering energy efficiency

Alternitive building books and videos from Cal*Earth

greenhomebuilding.com

dirtcheapbuilder books

http://www.northcoast.com/

dreamgreenhomes.com Source for alternitive building plans

Dave's Dome Info Page

More Dome Picts

Monolithic Domes

Pictures of a dome in construction

Dome construction Co

Sustainable Living Systems.

http://www.monolithic.org/

Underground

http://www.daviddarling.info/encyclopedia/E/AE_earth-sheltered_buildings.html

http://www.earthshelteredhome.com

The Fifty Dollar and Up Underground House Book

Earthship

greenhomebuilding.The Complete Book of Underground Houses

http://www.homedit.com/earthship-homes-made-of-recycled-tyres

http://www.daviddarling.info/encyclopedia/E/AE_earthship.html

Shipping container

http://weburbanist.com/2008/05/26/cargo-container-homes-and-offices

Adobe

http://en.wikipedia.org/wiki/Adobe

http://www.adobebuilder.com/

http://oikos.com/library/adobe/

Earth Bag

http://www.earthhomesnow.com/sandbag-houses.htm

ICF

The Benifits of ICF

More Pictires of ICF building in progress NKS

ICF DIRECT

Build Block

Quad Lock

California Energy Commission

SIP

More info on SIP

betterbuilding.com

www.ibpanels.com

HEMPCRETE

http://www.hemp.org/news/hempcrete-hemp-building-materials

Aircrete

http://www.domegaia.com/air-crete.html

© !deaman !nk. 2021